Nitrotech

Maximum Performance and Uninterrupted Production

Nitrogen generators are designed to provide continuous and efficient nitrogen production. The system, consisting of CMS filled columns, separates and holds all gases (O₂, CO₂, etc.) except nitrogen in the air under pressure. This process is carried out by the pressure swing adsorption (PSA) method.

Optimum Efficiency and Economical Solutions

In order to meet the varying nitrogen purity and pressure requirements for different applications, the generator selection should be made in a way that both fully meets the need and offers the most economical solution. Nitrogen generators have the capacity to produce nitrogen at different purities, but the production amount varies depending on the purity level.

Low Cost and High Efficiency

Thanks to its unique design and advanced technology, NitroTech Nitrogen Generators produce high purity nitrogen using less compressed air compared to similar systems on the market. In this way, operating and maintenance costs are minimized.

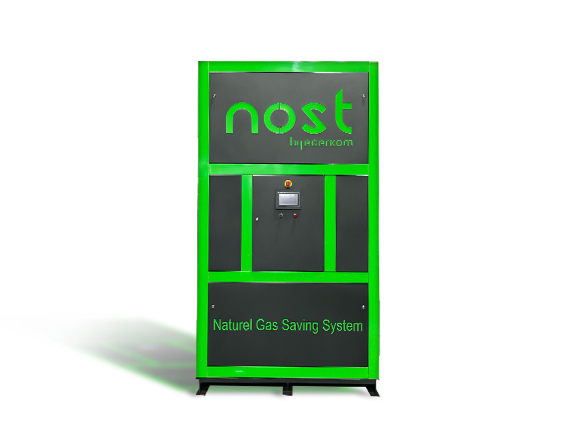

Nost

Increase Your Energy Efficiency with Natural Gas Saving System

The natural gas saving system reduces energy costs for businesses by ensuring that energy is used in the most efficient way. By optimizing natural gas usage, this system offers an environmentally friendly approach and reduces the carbon footprint of businesses.

Smart Control

Thanks to advanced sensors and automation technology, it provides the most appropriate gas flow for your energy needs.

Easy Integration

This system, which can be easily integrated into your existing energy systems, offers maximum efficiency with minimum interruption.

High Efficiency

The system provides a significant reduction in your energy costs by minimizing your natural gas consumption.

Coldnitro

ColdNitro is a cooling system that eliminates problems caused by high temperatures in the summer months in powder paint booth groups and operates with low energy consumption. Thanks to Paintro's high purity nitrogen, it provides cooling down to 15°C without condensation and solves problems such as surface defects, excess consumption, and screen blockage caused by hot compressor air.

Coldnitro offers energy savings by reducing the need for air-conditioned rooms, extends filter life by providing cold nitrogen in filter and cyclone returns. With its adjustable structure according to seasonal conditions, it offers superior performance by maintaining a constant temperature of 18°C in paint transfer hoses.

Paintro

Total Air Usage

The total flow rate of paint carrying and suction air coming out of the gun tip is of great importance in paint applications. In traditional systems, the total air amount is 4 m³/hour and the ratio of paint suction air to the total air is 50%. With PAINTRO technology, this ratio is reduced to 25% and the total air amount is reduced to 2.5 m³/hour.

Save Paint

Thanks to reduced dusting, better paint loading and equal paint spreading, paint savings of 10% to 30% are achieved with PAINTRO. This saving is valid for every application regardless of brand, model and facility.

Homogeneous Surface Distribution

Measurements made on flat surfaces in paint applications made with PAINTRO show that the micron thickness difference is reduced to +/- 5 micron levels. This ensures a smoother and higher quality surface.

Oxsitech

Safe and Economical Oxygen Production

Oxygen generators produce high purity oxygen by separating all gases except oxygen in the air thanks to the Zeolite filled columns under pressure. It works with PSA (Pressure Swing Adsorption) technology, providing an uninterrupted and efficient production process.

Low Cost, High Efficiency

It is possible to produce oxygen economically and according to the needs without being dependent on oxygen cylinders. NitroTech Oxygen Generator provides a safe and sustainable oxygen source in every sector. It offers continuous and controlled oxygen production without the need for high-cost cylinder supply.

Advantages:

- It produces oxygen up to 99% purity from compressed air.

- By optimizing oxygen consumption, it ensures return on investment within 1-2 years.

- Compact and easy installation: Compressed air line and electrical connection are sufficient.

- It eliminates cylinder change and logistics costs with continuous oxygen production.

Chemical Air Dryer

High Performance Air Drying Technology

Chemical air dryers operating on the PSA (Pressure Swing Adsorption) principle have been developed for applications requiring high quality compressed air. The dew point is reduced to -20°C, -40°C and -70°C levels, preventing condensation and corrosion.

Uninterrupted and Reliable Production

Üretim süreçlerinde yoğuşmadan kaynaklanan bozulma ve kirlenme risklerini ortadan kaldıran NitroTech Kimyasal Hava Kurutucu, düşük enerji tüketimi ile maliyet tasarrufu sağlarken, işletmeler için kesintisiz ve güvenilir hava kurutma çözümü sunar.

Wide Range of Use

Chemical air dryers are used in many sectors, especially the chemical and pharmaceutical industry, laser cutting systems, paint shops and petrochemical plants. These systems, which are also preferred in medical breathing air systems, the food industry and quality painting applications, offer a reliable solution in all industrial processes requiring low dew points.